Our eyes are critical to how we perceive and interact with the world around us. Without sight, that interaction changes drastically.

Our eyes are critical to how we perceive and interact with the world around us. Without sight, that interaction changes drastically.

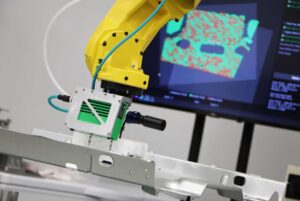

In automation, equipment like volumetric vision sensors act as the “eyes” for robots.The right set of “eyes” can provide many benefits beyond just “seeing.”

Here are four key areas of automation where 3D vision from Liberty Robotics provides significant benefits:

1. Robot Guidance

In automation, robots perform physical tasks based on programmed input. Without any additional input, a robot only does what it is programmed to do.Volumetric 3D robotic vision guidance gives the robot that set of “eyes” so it can adjust to variations it encounters.

This capability is especially important in high-precision applications, such as automotive cosmetic seam sealing. In this example, a seam that is not sealed accurately can compromise the structural integrity of the entire car. The robot must know where the part is to perform accurate work, making precise vision guidance essential.

Volumetric vision guidance gives the robot the ability to adjust the work performed by giving it a comprehensive view of the part. The vision system provides an offset, representing the distance and rotation by which a part has moved from its training position.

The robot applies the offset as an adjustment to the local frame to accurately complete its process, highlighting just one of the many ways vision guidance impacts automation.

2. Tooling

In terms of tooling and machine vision correlation, tooling holds the part in place so the vision system can interface with it effectively. The right 3D vision guidance system opens the doors to many tooling options. Hard tooling offers the most repeatable part position, but that rigidity can limit process flexibility.

Many processes utilize Automated Guided Vehicles (AGV’s). AGV’s offer greater flexibility and make systems more universal. However, repeatable positioning of AGV’s, while good, is not perfect.

The right volumetric vision guidance system can accommodate large or small position variation of the work area(s) while maintaining the accuracy required for the process. Incorporating 3D vision enhances process flexibility and continuity without compromising the process accuracy.

3. Data Collection

Most (if not all) engineers will agree: the more data, the better. However, the data must be meaningful. Case in point, Liberty Robotics vision guidance software not only tracks positional offset results, but also tracks data including carrier ID, system performance metrics, and process settings changes, to name a few.

All of this is useful information, not only for the performance of the vision system, but for continuous improvement of the overall automation process.

Liberty Robotics software stores data and provides a visual representation of the data, which makes it easier to identify performance trends. The system can export this information, which can be used in custom reports and analyses.

Thus, having useful data in accessible formats, as offered by by Liberty Robotics’ vision guidance systems, benefits the customer and system operators for the better.

4. Optimization

Continuous improvement and optimization are key in manufacturing. Greater flexibility and universal systems in automation provide a significant advantage. Flexibility and universality are significantly enhanced by incorporating

When critical components in an automation process have a high standard of flexibility, like robotic vision guidance, so does your process.