VFix

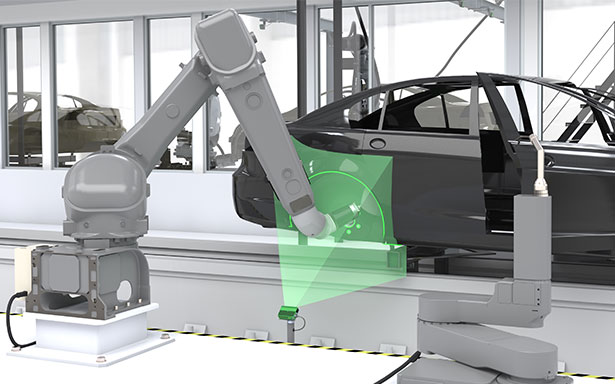

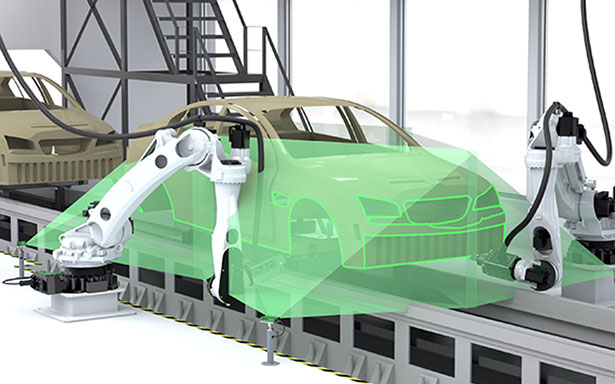

VFix uses stationary mounted sensors to measure six degrees of freedom offsets on large parts or vehicle bodies.

VFIX™ BENEFITS

FAST

VFix is the fastest robot guidance system available, providing 6 degrees of freedom offsets in milliseconds.

DEPENDABLE

VFix is not affected by ambient factory lighting and requires no external lights, which reduces faults and downtime.

FLEXIBLE

Systems easily accommodate unlimited model changes and style additions, requiring no additional sensors.

ROBUST

VFix is built to withstand punishing factory conditions and keep on working.

VERSATILE

It can dependably calculate the largest part-to-part shifts and rotations of any guidance system available.

SIMPLE

Installation, operation, adjustments, and maintenance are quick, easy, and economical.

APPLICATIONS

VFix™ solutions are specifically designed for 3D vision robot guidance with large parts or bodies in a manufacturing process.

VFix™ quickly and effectively scans the entire object in one action, capturing the data needed to guide robots that are handling parts, applying coating, sealing surfaces, and performing numerous other functions.

HOW IT WORKS

VFix™ utilizes 1 to 6 volumetric sensors to generate accurate offsets in six degrees of freedom. By using less hardware, the offsets are calculated quickly and reliably. When a large part or body is moved into position, VFix™ determines its position and orientation, calculates the offsets, and sends the information to the robots.

WHAT’S INCLUDED

Liberty Robotics provides everything you’ll need for a complete vision system – proprietary sensors, high performance industrialized Windows based computer (IoT embedded), proprietary software license, and industrial hardware (cabling, connectors, etc.)

Every component is designed to withstand harsh factory conditions.

Unlike other systems, ours are designed with the end user in mind. They are simple and easy to setup, use, change, and maintain. Our 24/7 service and support team is always ready to help.

QUICK CASE STUDY

Reducing Cost and Maintenance Frustration

Challenge – An automotive manufacturer had an existing vision system installed in their plant for a sealing application. The system took up space, was challenging to maintain, and required many different cameras to achieve desired vision guidance. It was not user friendly and proved costly when different parts were added to the line.

Solution – VFix replaced this system to reduce cost and maintenance frustration. VFix has larger field of view, which means that multiple different parts and sealant applications could be supported with a single set of cameras. This reduced the amount of space the previous vision system took up and allowed plant workers to easily use and maintain the system.

Outcome – The manufacturer loved the system and its ease of use and versatility. They currently have over 50 VFix products installed nationwide. Liberty Robotics successfully reduced cycle time and maintenance costs.