Greater 3D Robot Guidance Flexibility

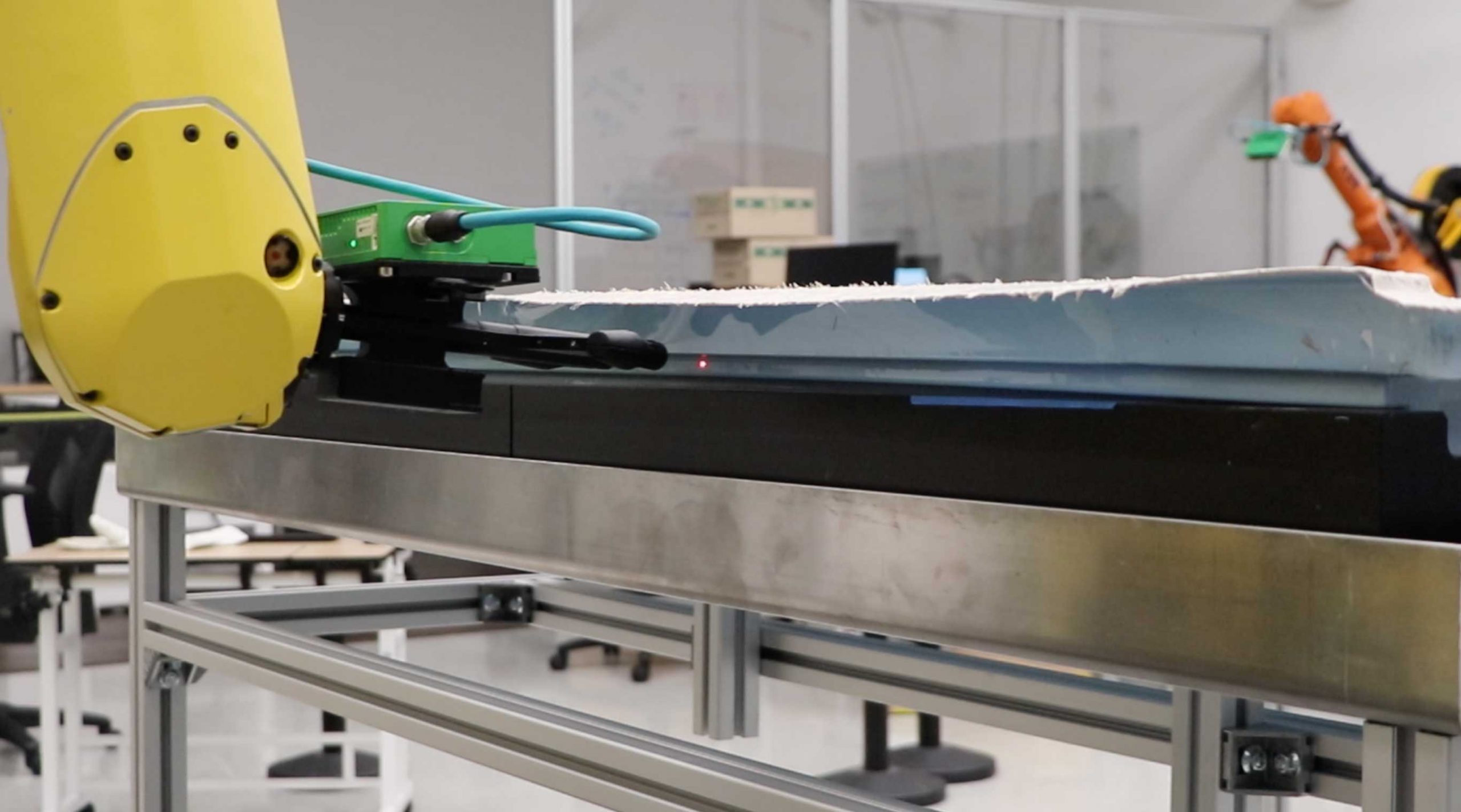

Liberty Robotics V-Guide™ and VFix™ robot guidance products are typically intended for use on rigid, repeatable parts. Recently, Liberty Robotics test engineers were tasked with assessing the V-Guide™ system accuracy on non-rigid, molded parts coated with fiberglass.

The engineers utilized V-Guide™ regional offsets to provide multiple offsets for one part across the entire surface. V-Guide™ measured the flexed part’s deviation from the unflexed training part so the robot could correct the work path to follow the flex in the part.

Although the V-Guide™ system was not able to achieve the +/- 1.5 mm touchpoint test accuracy result that the product is known for, it was able to meet the customer’s +/-3mm accuracy needs for the process. The customer was searching for an automation solution for this process for over a year before they contacted Liberty Reach.

The success of the test proved that Liberty Reach robot guidance products are flexible and can be applied to applications that do not fit the defined part requirements for VFix™ and V-Guide™.

Sarah Coleman | Product Manager

To stay current on all things Liberty Robotics, follow us on LinkedIn.

About Liberty Robotics

Liberty Robotics provides 3D volumetric vision guidance systems for robot applications. Our systems improve manufacturing, material/part handling, and logistics operations performed in industrial environments. We provide value by decreasing cycle time, increasing capacity and throughput, and improving automated operations. Furthermore, Liberty Robotics 3D Vision Guidance systems increase repeatability and decrease faults and costly downtime. As the first company to deploy volumetric sensor technology on a high-precision manufacturing line, we are the experts in volumetric vision guidance solutions.