As a result of more people working and shopping from home, automation technology became crucial for manufacturers and distribution centers to keep up with an expanding ecommerce industry. No one was prepared for the numerous impacts of a global pandemic. Many manufacturers slowed or halted production due to employee safety concerns while trying to navigate the unprecedented situation; meanwhile, the demand for products and goods surged.

Labor shortages in plants prevented regular shipments and online orders from being fulfilled on time. More manufacturing plants and distribution centers now find themselves needing to automate several processes to compensate for a loss of labor and an increase in product demand. Although robots are essential and beneficial for most manufacturing operations, they are not perfect and cannot always achieve desired results or meet the accuracy requirements for a specific job.

In the past, the limitations of robots have made some processes poor candidates for automation. Robots are efficient and precise but without machine vision they cannot achieve high accuracy if the position of the work target varies. Most conveyors used in manufacturing and shipping cause the robot’s work targets to shift while they are transported. Liberty Reach 3D machine vision uses volumetric sensors to detect part shifts and rotations. The part position is sent directly to the robot to correct its work path. Installing robotic vision technology allows robots to perform a greater variety of tasks with better accuracy.

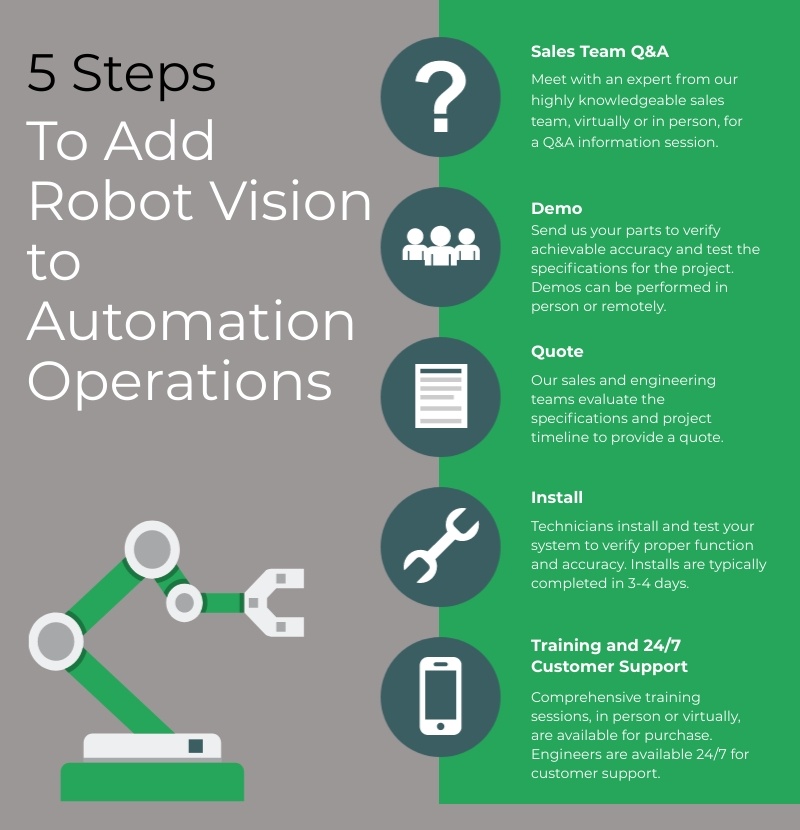

If you have ever considered adding 3D robot vision to your process but don’t know where to start, check out this quick break down. Contact us for more information on setting up a demo and adding machine vision to your robot operations.