In the automation industry, it is crucial to determine the suitability of a 3D machine vision system for a specific application. This underscores the significance of the comprehensive feasibility testing process, meticulously crafted to guarantee optimal outcomes. The following steps outline Liberty Robotics’ step-by-step process to ensure peak machine vision performance for automated tasks.

Step 1: Understanding Work Zone Restrictions and Process Flow

The first step in our feasibility testing process is to understand the work zone restrictions and process flow. We begin by replicating the automation work zone constraints in our robot lab and assess limitations. This information concurrently helps to identify potential sensor views of the customer’s part. We systematically explore all available options to carefully select the most effective one.

Step 2: Requesting a Sample

In instances where the customer’s part exhibits a unique design or material, the next step is to request a sample. For molded or non-rigid parts, we go a step further by requesting a stack of parts. This proactive approach enables a deeper understanding of the part, facilitating tailored tests.

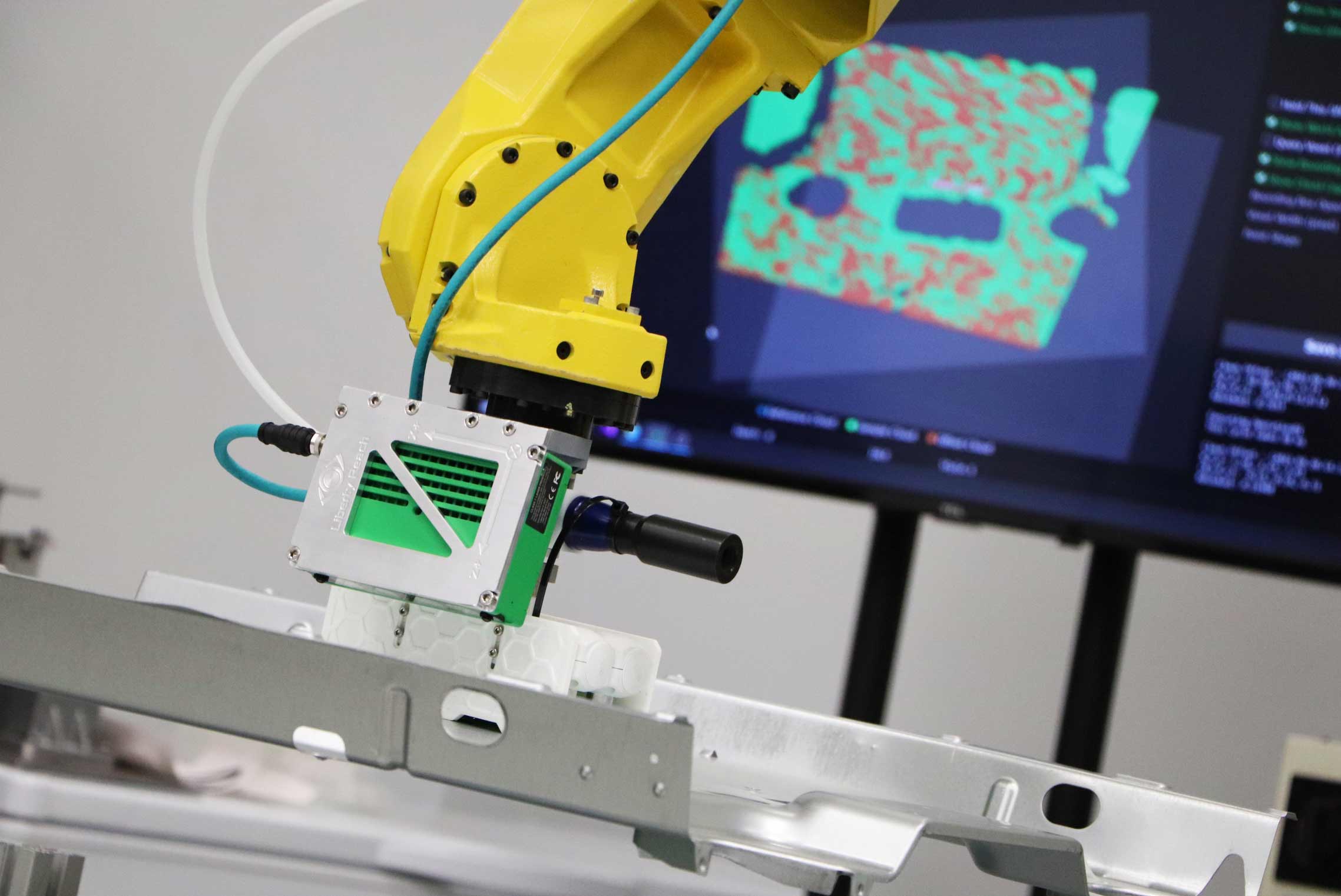

Step 3: Testing Accuracy

Moving forward, our focus shifts to testing the accuracy of the 3D robot guidance vision system using the customer’s part. We experiment with diverse combinations of sensor views and software features to ascertain the optimal accuracy. This step plays a pivotal role in ensuring the system’s optimal performance in real-world conditions.

Step 4: Video Demonstration

Proceeding further, we document the test through a video demonstration, showcasing the system’s capabilities. This visual representation serves as proof of the application and allows the customer to see the system in action.

Step 5: Presenting the Results

Subsequently, we present the results to the customer through a video call or an in-person meeting. This interactive session enables customers to pose queries and offers us the chance to address any concerns that may arise.

Step 6: Re-testing

In cases where it becomes necessary, we conduct re-testing to more accurately align with the customer’s process flow or work restrictions. This iterative approach ensures the effectiveness of our system in the customer’s specific environment.

Step 7: Completing the Process

Ultimately, the culmination of our efforts ideally leads to the customer finding the right solution with Liberty Robotics’ systems. However, it’s essential to acknowledge that sometimes testing reveals that the system’s accuracy, given the restrictions, is not always the correct vision system for the application. In such instances, our commitment to honesty and transparency takes precedence, fostering trust with our customers.

In conclusion, our presale testing process stands as a testament to our commitment to delivering the optimal automation solutions for our customers. Though meticulous and thorough, we firmly believe that it is a crucial component of both our success and the success of our valued customers.

Contact us today to get started on a complimentary feasibility study. Stay up to date all on our product offerings and information, follow us on LinkedIn.